Rotary Kiln Chain

- Home

- Products

- Chains & Accessories

- Industry Chain

- Rotary Kiln Chain

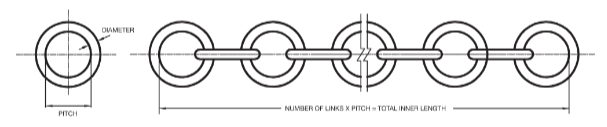

| Diameter (inch) |

Pitch (inch) |

Weight/Ring (Lbs.) |

Weight/ 100feet(Lbs.) |

|---|---|---|---|

| 5/8 | 2-3/4 | 0.95 | 413 |

| 5/8 | 4 | 1.63 | 497 |

| 3/4 | 2-9/16 | 1.43 | 672 |

| 3/4 | 2-3/4 | 1.39 | 605 |

| 3/4 | 3 | 1.48 | 592 |

| 3/4 | 2-9/16 | 1.48 | 693 |

| 3/4 | 2-3/4 | 1.54 | 672 |

| 3/4 | 3 | 1.65 | 665 |

| 3/4 | 3-5/64 | 1.70 | 663 |

| 3/4 | 3-1/8 | 1.72 | 655 |

| 3/4 | 4 | 2.05 | 625 |

| 7/8 | 3 | 2.05 | 822 |

| 7/8 | 3-1/8 | 2.14 | 815 |

| 7/8 | 4 | 2.51 | 766 |

| 7/8 | 3 | 2.25 | 902 |

| 7/8 | 3-1/8 | 2.36 | 899 |

| 7/8 | 4 | 2.51 | 765 |

| 7/8 | 4 | 2.51 | 765 |

| 1 | 3 | 2.71 | 1088 |

| 1 | 3-1/8 | 2.85 | 1083 |

| 1 | 3-1/2 | 3.09 | 1057 |

| 1 | 4 | 4.35 | 1021 |

| 1-1/8 | 4 | 4.30 | 1310 |

| 1-3/16 | 4 | 5.03 | 1532 |

| 1-1/4 | 4 | 5.84 | 1781 |

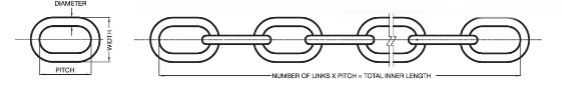

| Diameter (inch) |

Pitch (inch) |

Outside Width |

Weight/Ring (Lbs.) |

Weight/ 100feet(Lbs.) |

|---|---|---|---|---|

| 5/8 | 2-13/64 | 2-1/8 | 0.644 | 350 |

| 5/8 | 2-15/32 | 2-3/8 | 0.914 | 440 |

| 3/4 | 2-3/4 | 2-5/8 | 1.263 | 549 |

| 3/4 | 3-1/8 | 3-1/8 | 1.600 | 613 |

| 7/8 | 3-25/64 | 2-59/64 | 1.850 | 659 |

| 7/8 | 3-1/8 | 3-1/32 | 1.905 | 728 |

| 1 | 3-19/32 | 3-1/2 | 2.580 | 866 |

| 1 | 3-19/64 | 3-1/2 | 2.860 | 941 |

| 1-1/8 | 3-7/8 | 4 | 3.565 | 1109 |

| 1-3/16 | 4-5/32 | 4-5/32 | 4.400 | 1277 |

| DIN Standard Material Number |

DIN Standard |

AISI Standard |

Weight | Weight/ | Structure | ||

|---|---|---|---|---|---|---|---|

| – | – | – | °C | °F | °C | °F | – |

| Carbon Steels | |||||||

| – | – | – | – | – | – | – | – |

View our brochure for an easy to read guide on all of the products offer.